Conveyor lubrication

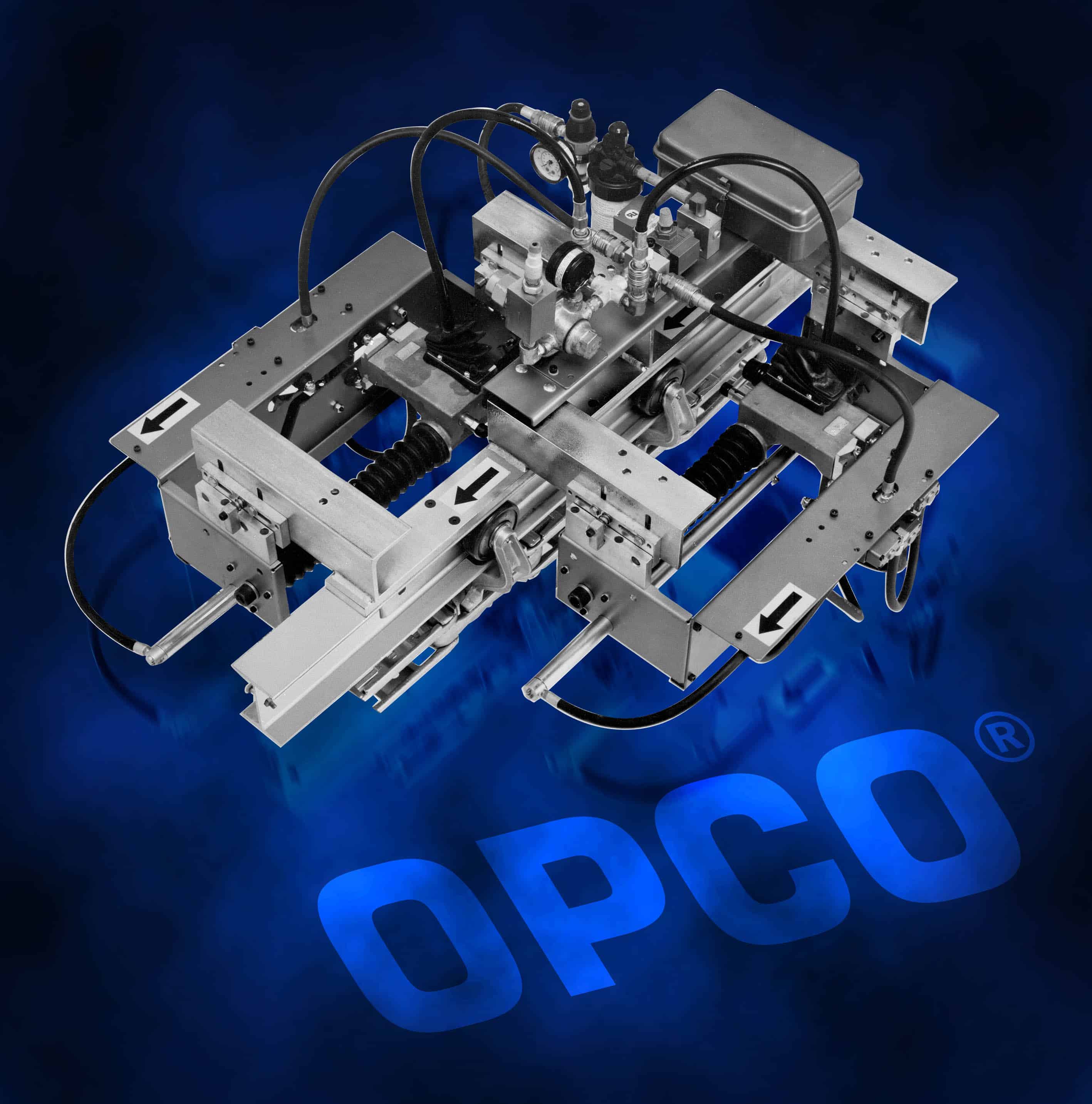

in this program, we have all products to lube and clean all types of conveyors. We can produce pneumatic and electric lubrication units for grease and oil. The units are designed to deliver a measured amount of lubricant to the conveyor wear points: Chain pins, chain links, closed or open trolley wheels, track and rollers. All units are full automatically working during the production is going on.