Pump to divider

The lubrication system is designed to guarantee the ever-increasing need for monitoring. The main distributor is supplied by several combined pumping elements. This in turn provides the lower Distributor, which then lead to a precisely defined amount of lubricating oil to each lubrication point.

Benefits of centralized monitoring of the pressure and monitoring each lubrication point. Precisely defined quantity for each lubrication Point.

Disadvantages

All compressor data must be known to determine the quantity per point precisely.

Special features

The system layout must be correct.

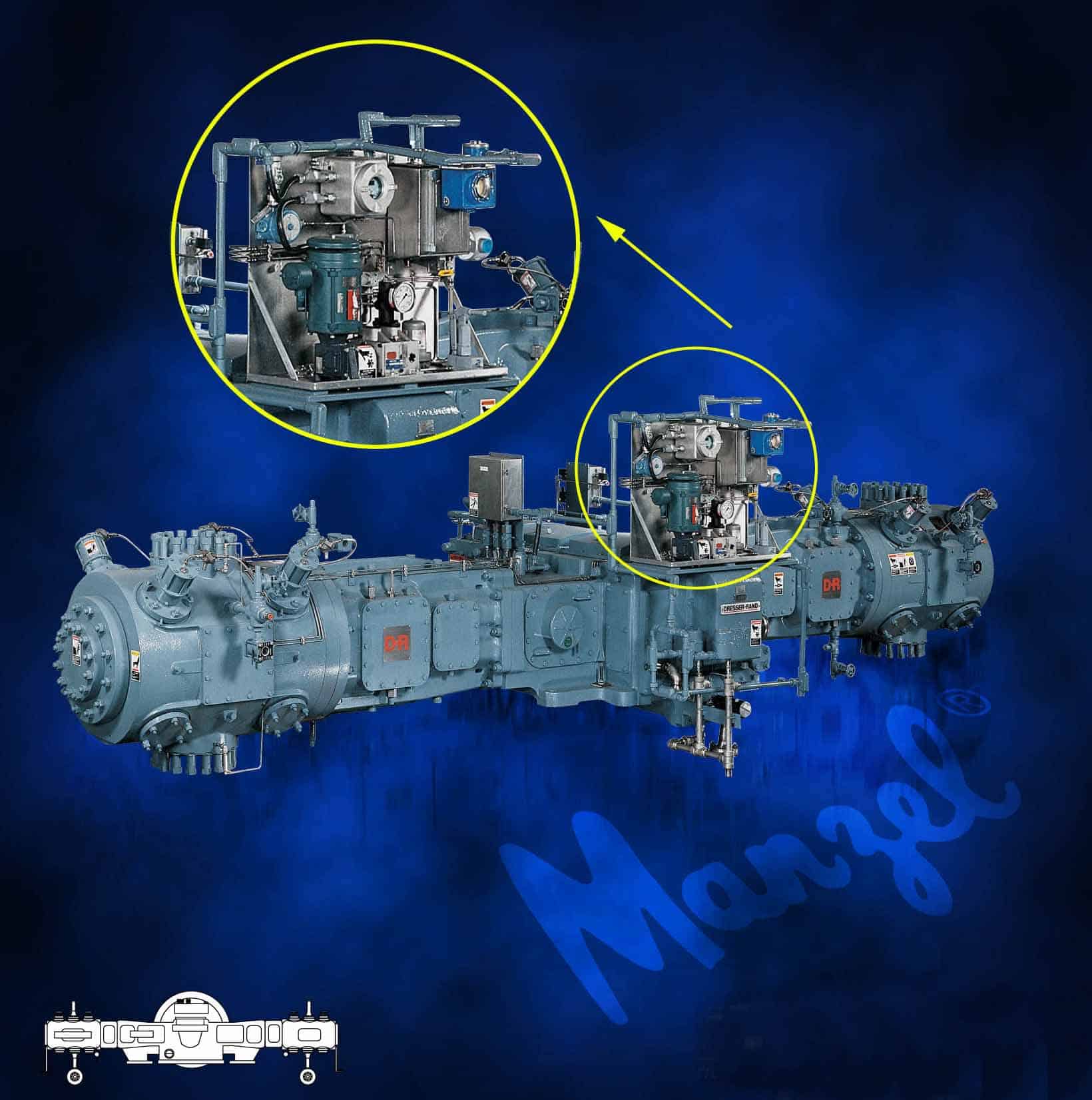

The Sentinel system

(see picture right)

Analyzes have shown that over 80 percent of compressor failures and repairs can be attributed to improper lubrication. Over lubrication leads to deposits in valves and cylinder heads. It leads to leaks, low efficiency and higher costs. The system must be switched off and repaired. In the worst case, it leads to the complete destruction of the compressor. The Sentinel system eliminates the need to manually set up dozens of pumps. It is monitored by electronic control.